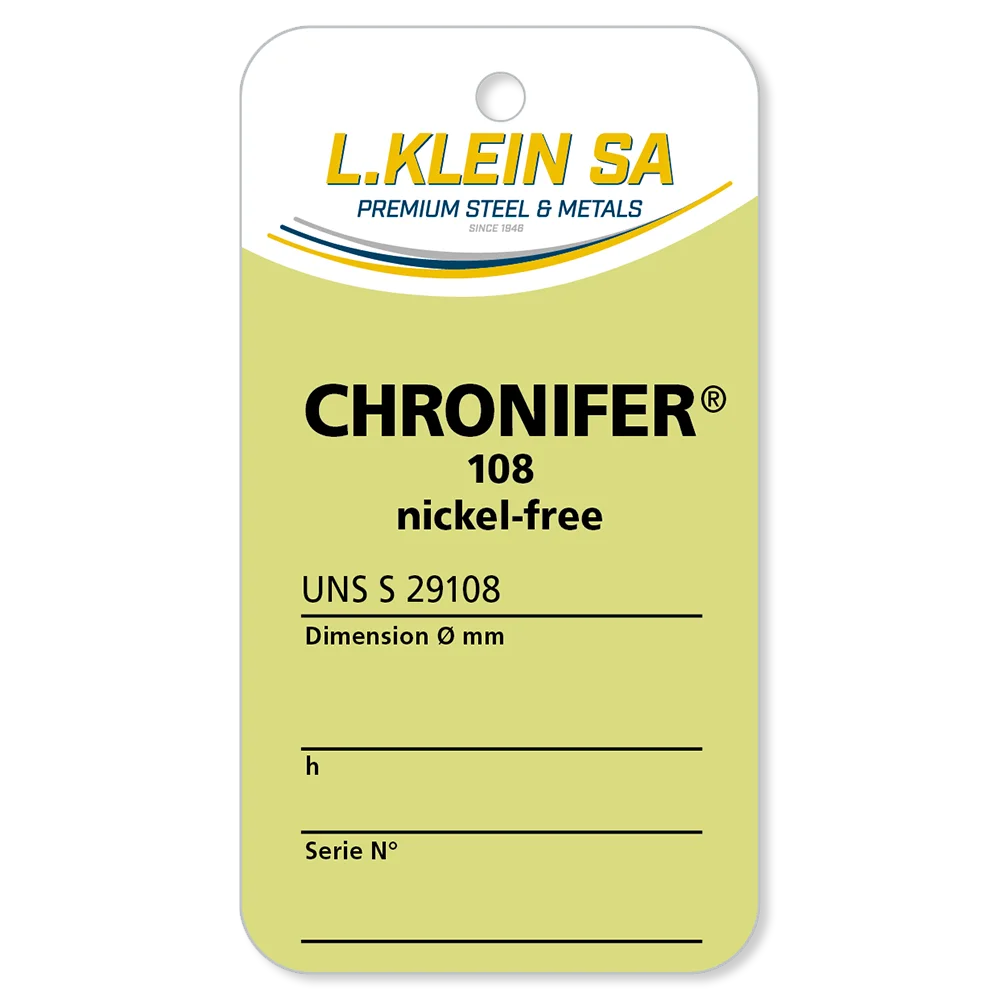

Nickel-Free Alloy Implant – Chronifer 108

The stainless steel used for implants must be corrosion-resistant and biocompatible. Since implants are always placed in the body, it is essential to aim for high biological tolerance when choosing the material.

Most of the time, these implants are made of chromium-cobalt-molybdenum alloy, austenitic steel, or titanium. The latter is especially used in patients suffering from contact allergies (to chromium and nickel).

The CHRONIFER 108 steel is a nickel-free austenitic stainless steel. It is free of delta ferrite (∂), non-magnetic, and well-suited for all applications that require both high strength and good corrosion resistance. These properties make this steel particularly attractive for implants and joint replacement prostheses.

Features and Characteristics

The CHRONIFER 108 steel is the nickel-free austenitic “BioDur® 108” from Carpenter. The substitution of Ni with Mn and a significant addition of N allow this steel to preserve its austenitic structure. The PESR (Pressure ESR) process ensures both its microstructural cleanliness and a uniform, reproducible microstructure. This results in a very tough steel with mechanical properties and fatigue resistance superior to those of a 316L steel, meeting the requirements of the ASTM F138 standard. This steel does not contain delta ferrite (∂). It is non-magnetic. Due to its metallurgy and low sulfur content, it particularly resists pitting and crevice corrosion.

The following characteristics make this steel perfectly suited for medical use (surgery):

High Mechanical Properties

Fatigue Resistance

Corrosion Resistance

Hypoallergenic Properties