What is free-cutting steel?

Free-cutting steel, also called machinable steel, is a category of steels that are easily machinable and produce short chips during the machining process. Because the chips are broken into small pieces, there are no long chips to wrap around the tools, allowing for efficient chip evacuation. The cutting speed can be increased significantly without having to check the machine frequently. The machines can produce parts unattended overnight. Free-cutting steel is produced in the form of bars and discs and contains 0.08 to 0.45% carbon, 0.6 to 1.55% manganese, 0.15 to 0.35% silicon, 0.08 to 0.3% sulphur and 0.05 to 0.16% phosphorus.

Free-cutting steel alloys

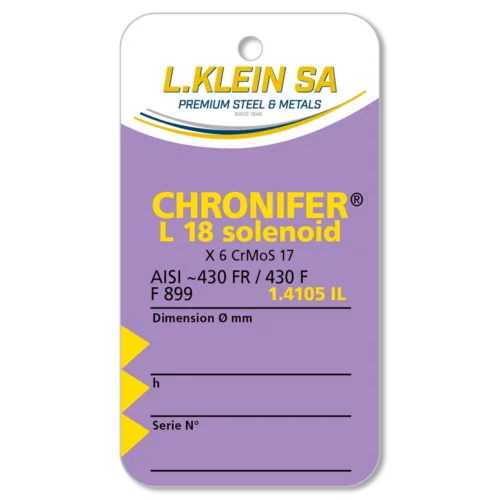

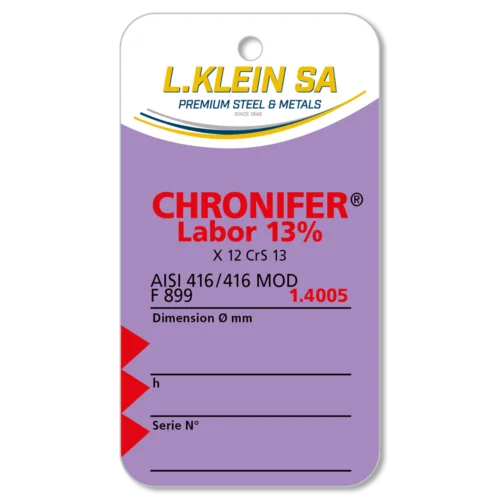

Free-cutting steel has a higher sulphur and phosphorus content than ordinary steels. Alloying elements commonly used in free-cutting steel include lead for carbon steel and sulphur for stainless steels. Other possible alloying elements are bismuth and tellurium. These alloying elements greatly improve processing speed even at low weight percentages, ensuring tool durability.

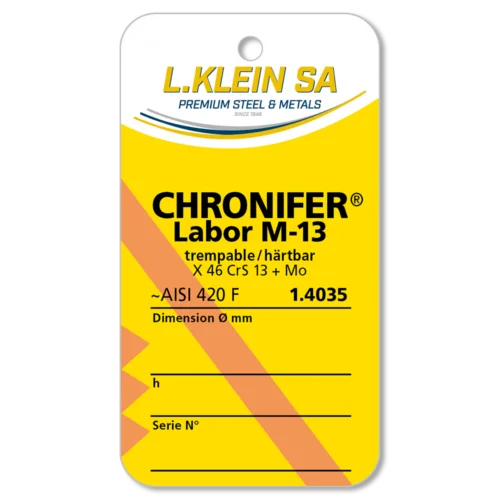

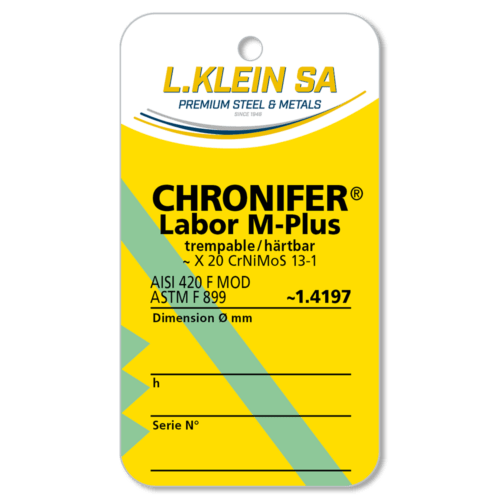

Some grades of free-cutting steel can also be hardened. These grades are suitable for manufacturing parts in large quantities, such as screws, gears, axles and many others.

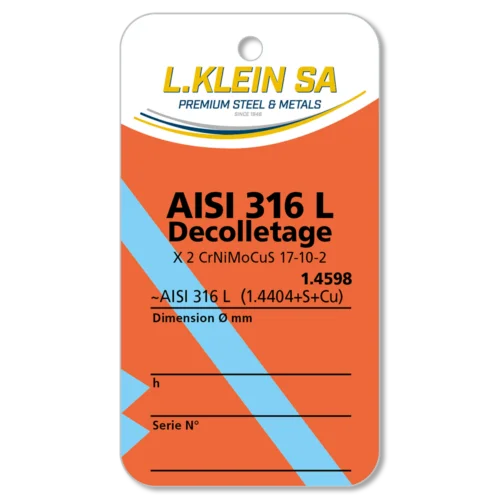

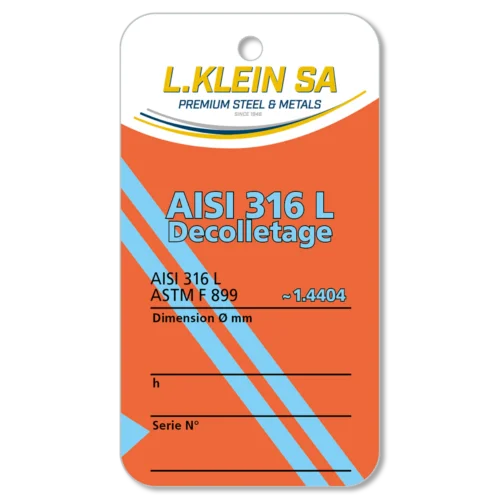

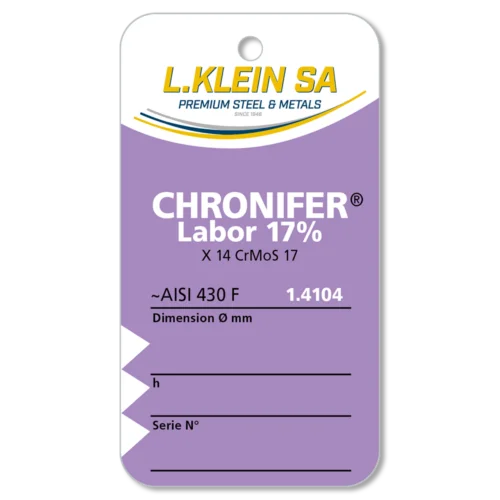

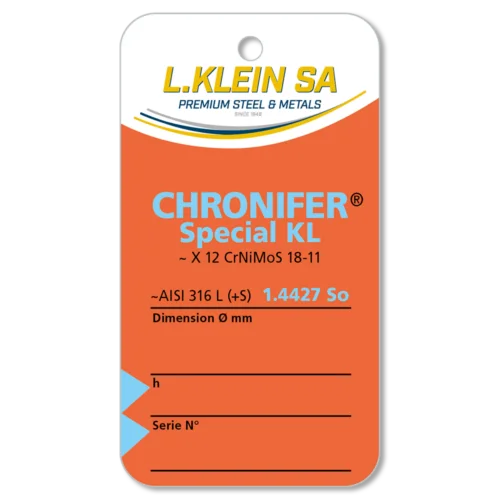

We offer a wide range of free cutting steels such as 11SMn30 /11SMnPb30 /11SMnPb37. Some popular free cutting steels in our stock are Laboratory Pb (1.0759), LAW 100 Pb (1.1268), LAW 100 X (1.1268), Chronifer Special D 18/8 (1.4305), AISI 316 L Décolletage (1.4598), Chronifer Special KL (1.4427).

L. Klein AG is a reliable supplier of free cutting steel and also offers small quantities in the form of 3-metre bars and washers in stock. We offer excellent multilingual support and reliable shipping. Although we have a local delivery service for the Swiss market, we deliver our steel throughout the EU and worldwide. Our main European customers are in Germany, France, Italy and Spain.